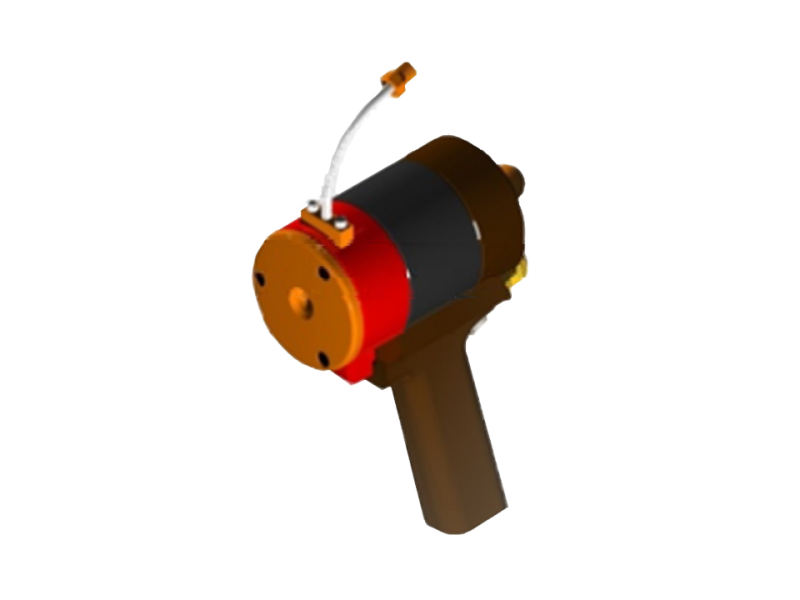

WireJet-96 Combustion Wire Spray Torch

- Products

- WireJet-96 Combustion Wire Spray Torch

The Wirejet-96 is an equivalent to the 12E Combustion Wire Spray Gun. It is built for continuous hard service and will perform efficiently and economically when properly operated and maintained. Our entire line of WireJet guns is perfect for hand-held, fixed or mobile applications. The Wirejet-96 is a lightweight wire gun that uses an air fed turbine to feed the wire. This is one of the most common wire guns on the market and can be used on most types of wire.

Wirejet-96 Combustion Wire Spray GunThe WireJet-96 Combustion Wire Spray Gun has been designed and built to be one of the world’s best hand torch for producing flame sprayed coatings with metalizing wires. It has a universal gas head, which can be adapted to use the most common fuel gasses. The standard gun is set up to spray 3.17mm (1/8”) wire with oxy/acetylene fuel. Suitable hardware is available for handling all standard wire sizes ranging from 4.76mm (3/16”) down 1.58mm (1/16”).

The controlled speed range of the WireJet-96 Combustion Wire Spray Gun is from about 0.45mm of wire per minute with standard gears to approximately 13.5 mm/min with the special easily installed, high-speed gear set. The high-speed gear set is for continuous high-speed spraying of the lower melting point metals such as Aluminum, Babbitt, Tin, and Zinc.Wirejet-96 Combustion Wire Spray Gun Features:

- An improved version of the WireJet-96’s siphon jet gas head produces high spray rates, low gas consumption and extreme resistance to back-fire and its effects.

- Nozzle-to siphon plug seals are “O” Rings, instead of being lapped surfaces, which are difficult to maintain.

- A new grease seal on the high-speed turbine shaft minimizes leakage of lubricant.

- A sight plug permits checking the level of lubricant in the gear case without the need to open it, eliminating a source of contamination.

- The gas head valve provides long service life with minimum maintenance. Worn or damaged valve parts are easily replaced in the field.

- High-quality nozzles and air caps provide excellent coatings at very high spraying speeds.

- The nozzle, siphon plug and front wire guide assemble as a unit, which can quickly and easily be removed and replaced when changing wire size, or for service.

- WireJet-96 Gun’s controlled-power governor provides increase power and more stable wire speed.

- The gear chamber contains a built-in pump for circulating the gear lubricant. This coupled with large rugged gears and improved gear chamber sealing provides longer gear life.

- The drive rolls and wire guides are made of hardened stainless steel for high resistance to wear and corrosion.

- The gun-mounting stud is centrally located, making it very easy to adjust the gun position when mounted to automated spray equipment.

- For convenience when changing wires, or to stop the wire feed momentarily while spraying, the gun has a quick action wire grip-release lever. A simple, effective wire snubber is provided at the back of the gun to keep the wire from slipping out of the gun when operating on a start-stop basis.

- The gun has a simple wire grip adjustment for varying the bite of the drive rolls on the wire. This independent adjustment helps extend drive roll life.

- ID nozzle extensions are available in 1, 2 and 3-foot lengths.

PPS Wirejet-96 Combustion Wire Spray Gun demonstration videos

Combustion Wire Coating – Wirejet 96 with a 1 Foot, 45° ExtensionCombustion wire spray application demo video. Spray coating a Metal Coupon mounted in the RM2 Spray Booth using the Wirejet-96 Combustion Wire Spray Gun with a 1 Foot, 45° Extension.

Combustion Wire Coating – Zinc Coating a Metal Plate using Spray Booth, Wirejet 96Zinc spray application demo video. Spray coating a Metal Plate mounted on the RM2TTAC Turntable in the RM2 Spray Booth using the Wirejet-96 Combustion Wire Spray Gun and wire fed Zinc.

Copper Spray Coating a Vase using Spray Booth, Turntable, Wire Spray GunCopper spray application demo video. Spray coating a Concrete Vase mounted on the RM2TTAC Turntable in the RM2 Spray Booth using the Wirejet-96 Combustion Wire Spray Gun and wire fed copper.

Related Products

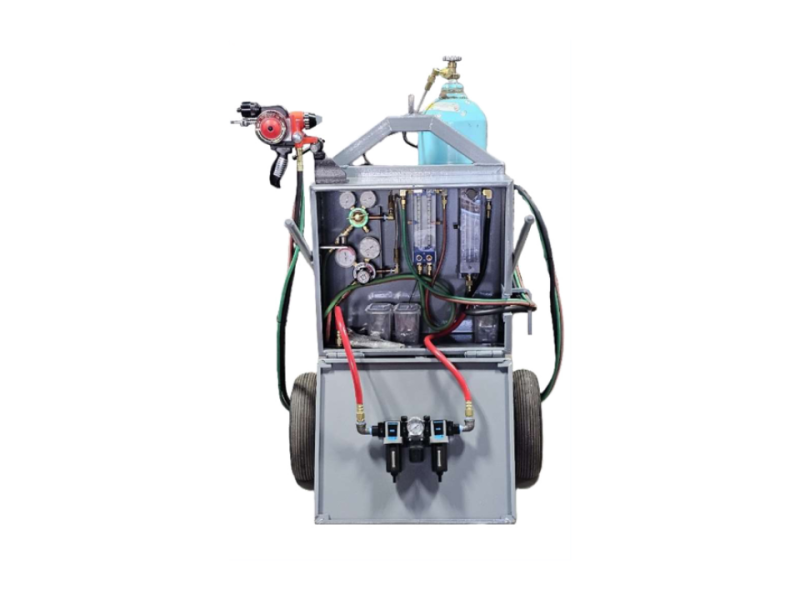

Mobile System Cart

The Plasma Powders & Systems Mobile Systems Cart is a heavy-duty, portable system cart compatible with the following Powder and Wire systems: Wire Jet96, Wire Jet98, CorroSpray, PowderJet85.

View DetailsSG-100 Type Plasma Gun

The SG-100 is suitable for both high volume production applications as well as lower volume applications where system flexibility is required.

View DetailsPowderJet 85 Combustion Powder Spray Torch

PowderJet 85 Combustion Powder Spray Torch is a thermal spraying torch used to deposit combustion thermal spray powders on to solid work surfaces.

View DetailsPowderJet 86 Combustion Powder Spray Torch

The Powderjet-86 Combustion Powder Spray Torch 86 is a thermal spraying torch used to deposit combustion thermal spray powders on to solid work surfaces.

View DetailsWireJet-96 Combustion Wire Spray Torch

The Wirejet-96 is an equivalent to the 12E Combustion Wire Spray Gun.