The new combination process provides an alternative to chrome and other coatings.

When seals and seal systems are mentioned, elastomers and compliant materials come to mind. Seldom is thought given to the backbone of the sealing system, the sealing surface. Although many changes have been made with elastomeric members, alterations are also happening with the sealing surface regarding materials and application methods. One notable change is benefiting the hard chrome industry, including repair and rework shops servicing pulp and paper mill rolls, heavy equipment, oil and gas drilling machinery, landing gear and hydraulic cylinders and pistons.

Chrome and Alternatives

Hard chrome plating on rods has presented a particular problem as typical hard chrome plating includes the production of hexavalent chromium compounds. The National Institute for Occupational Safety and Health (NIOSH) classifies all such compounds as occupational carcinogens. In 1996, the U. S. government formed the Hard Chrome Alternate Team (HCAT), with the goal of eliminating these carcinogens from the workplace. A key driver in this program was The Strategic Environmental Research and Development Program (SERDP), DoD’s environmental science and technology program in partnership with DOE and EPA. The HCAT team included representatives from industry and the US and Canadian governments and was dissolved in 2007 once its objective was achieved, a rarity for government programs.

The HCAT project centered on the “line-of-sight” thermal spray process with a focus on the HVOF system that was the highest kinetic energy process available at that time. Thermal spray covers a group of coating processes where finely divided metallic or nonmetallic materials are deposited in a molten or semi-molten condition to form a coating. The coating stock may be in the form of powder, ceramic rod, wire or molten materials. Many different thermal spray processes are in use: wire arc, wire flame, powder flame, plasma, high-velocity oxy/fuel (HVOF) and high-velocity air/fuel (HVAF).

A significant advantage of thermal spray coatings is the variety of available coating materials. Materials used in specific applications are chrome carbide, tungsten carbide nickel chrome, tungsten carbide cobalt chrome, stainless steels, and metals. The variety of coating materials allows tailoring the process to specific applications in various operating environments where electrolytic hard chrome would not perform well, or in fact, may not be considered at all.

HVOF and HVAF Processes

HVOF is used throughout the aircraft industry and in military depots where aircraft are repaired. New aircraft landing gear is designed with an HVOF coating on the landing gear cylinder. Many other major components also use the same technology, including aircraft hydraulic actuators, engines, helicopter dynamic components, and propeller hubs. Besides eliminating the problematic carcinogen, hexavalent chrome, from past processes used in the repair and rework settings, HVOF coatings last longer and demonstrate less wear and corrosion. Note: though chrome is included in some of these coatings, hexavalent chrome is not produced in the process.

In HVOF guns, a mixture of oxygen and gaseous or liquid fuel is fed into a chamber where ignition and continuous combustion occur. The resultant hot gas exits through a converging-diverging nozzle. The jet velocity is supersonic at the exit of the barrel. A powder feedstock is injected into the gas stream and accelerates up to 800 m/s. The stream of hot gas and powder is directed towards the surface to be coated. The powder partially melts in the stream and deposits upon the substrate with a resulting coating of low porosity and high bond strength.

In HVAF guns, spray powders are heated and accelerated by combustion products of hot compressed air and fuel gas. Fuel gas can be propane, LPG with a high content of butane, propylene, MAPP or natural gas.

A mixture of air and fuel gas flows into the combustion chamber through hundreds of orifices of a ceramic insert. Initial ignition of the mixture by a spark plug results in heating of the insert above the auto-ignition temperature of the mixture. The hot insert continuously ignites gases, providing stable combustion in a wide range of air: fuel ratios and gas pressures. The air cools the gun, and this preheated air is used for combustion.

HVAF-applied coatings protect parts, vessels, and structures against abrasion, erosion, and corrosion and benefit surface restoration, conservation and preservation. HVAF is also used for spraying the internal diameters of pipes in preparation for other processes through the application of a thin layer surface and coating stripping.

Combining the Two Processes

HVAF and HVOF have been merged into a single system (HVAF/HVOF) that offers the highest spray rates in the industry in either mode. The HVAF/HVOF thermal spray system uses air as the primary oxidizer and oxygen to elevate the temperature, thereby optimizing the process with breakthrough results. The addition of oxygen provides all existing HVOF owners and new prospects a reliable and less expensive coating with high quality. Existing HVOF specifications can be achieved and exceeded using the convertible system. Users can achieve a 0.002-in. the thick corrosion-proof coating that holds up under high pressure and can be polished to an RA 4 finish without grinding.

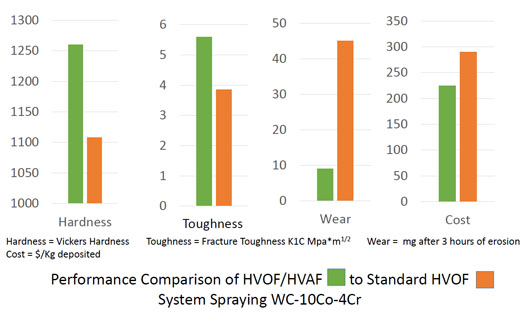

In comparison to the HVOF process, the combined process provides a significant increase in the Vickers Hardness of WC-10Co-4 Cr coatings. Weight loss during silt erosion testing is less than 1/3 of the weight loss of the same coating applied with the traditional HVOF process. Furthermore, the cost per kilogram deposited can be as much as half that of using the HVOF process.

In summary, the HVAF/HVOF system produces very economically, high-quality coatings with easy to use, reliable equipment.

- HVOF mode delivers coatings of metals that meet HVOF specs with high spray rates and high DE.

- HVOF mode delivers coatings of hard metals that are extremely dense.

- Cost per kg deposited can be as much as half the cost of using the HVOF process.

- HVAF mode delivers higher quality than state-of-the-art HVOF with much higher spray rates and high DE.

- The equipment produces porous free chrome replacement coatings as thin as 0.002-in. thick. A 0.4 RA on an 86-10-4 coating with polishing can be achieved.