PPS 5K Machine Mounted Wire Spray Torch

- Products

- PPS 5K Machine Mounted Wire Spray Torch

The PPS-5K Wire Spray Torch is built for automated, mass production environments, having been designed to spray continuously for long periods while maintaining constant coating quality. The PPS-5K Wire Spray Torch boasts low gas consumption and is highly efficient to operate. This unit cannot be used in handheld applications.A machine-mounted combustion wire spray torch with a motor. This unit has an external control box that adjusts rate of spray.

When a heavy-duty torch is required for high-volume or continuous combustion wire flame spray production, the PPS-5K torch is a clear choice. The PPS-5K is built for automated, mass production environments, having been designed to spray continuously for long periods while maintaining constant coating quality. The PPS-5K has low gas consumption for highly efficient operation. Coupled with the ease of operation and simplified maintenance requirements, the PPS-5K combustion wire flame spray torch is a proven performer for any production environment.

This is an excellent choice for mass production coatings for synchron rings, piston rings, yoder mill tubes, shifter forks, sliding wear applications requiring self-lubricating properties and high-volume corrosion coating applications.

PPS-5K Wire Spray Torch Features:

- Heavy-duty, rugged design – built for high volume production environments.

- Simple operation – requires minimal operator training.

- Flexible wire choices – can be configured for use with hard or soft wires in a variety of diameters.

- Flexible fuel gas choices – to suit plant operational requirements and economics.

- Extra-sturdy tool post – ensures the torch will remain in its set position.

- Unique universal gas head – produces high spray rates with low gas consumption and is resistant to backfire.

- Gas head valve handle – allows instant start/stop of gas through the torch.

- O-ring seals between nozzle and siphon plug ensure safe and reliable operation and simplify torch maintenance.

- Precision wire feed control – provides precise control of wire feed rate.

- Dependable electric wire drive – regardless of wire drag for constant, uniform feed of coating material.

- Long gear life – designed with large, rugged gears coupled with circulating gear lubricant pump.

- Built-in sight plug – visually check the level of lubricant without the need to open the gear case.

- Simple maintenance and hardware changeover – the nozzle, siphon plug, and front wire guide assemblies can be easily removed and replaced as a complete unit.

- Available extensions: 1, 2 and 3 ft extension, Propane or acetylene.

Uses:Automated, mass production environment.

Pros:Easy to adjust spray rate. Easy to maintain. Continuous, efficient spraying.

Used with: Electric powered gun mounted wire feed motor.

Related Products

WireJet 98 Combustion Wire Spray Torch

The WireJet-98 Gun is an equivalent to the 14E Combustion Wire Spray Gun.

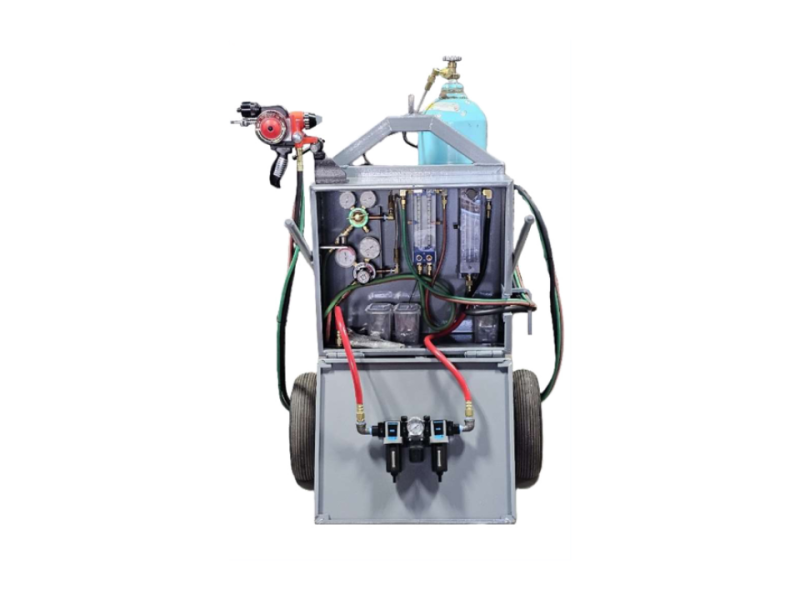

View DetailsMobile System Cart

The Plasma Powders & Systems Mobile Systems Cart is a heavy-duty, portable system cart compatible with the following Powder and Wire systems: Wire Jet96, Wire Jet98, CorroSpray, PowderJet85.

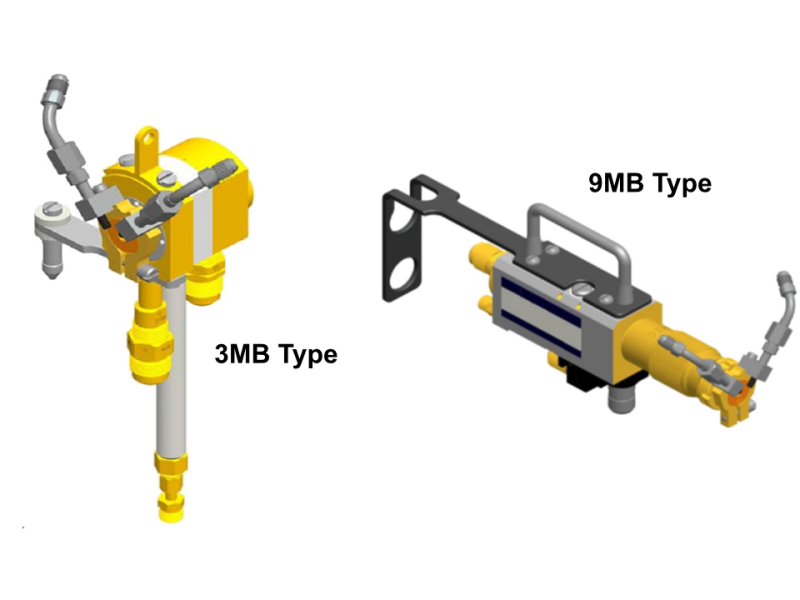

View Details3Mb and 9Mb Type Plasma Gun

The 3MB and 9MB plasma spray guns are general-purpose tools used for thermal spray applications, known for producing high-quality, consistent coatings of various materials.

View DetailsPowderJet 85 Combustion Powder Spray Torch

PowderJet 85 Combustion Powder Spray Torch is a thermal spraying torch used to deposit combustion thermal spray powders on to solid work surfaces.

View DetailsPPS 5K Machine Mounted Wire Spray Torch

The PPS-5K Wire Spray Torch is built for automated, mass production environments, having been designed to spray continuously for long periods while maintaining constant coating quality.