Handling Equipment

RM-2 Spray Booth

The RM-2 Spray Booth helps to isolate the spray operation. In many cases, the unit can be used in place of a spray room because dust, fumes and heat are drawn to the rear of the booth via a dust collection flange.RM-2 can be built with several optional part and torch handling options including built in turntable, lathe headstock, tailstock, single or dual traverse units and a robot mount swing arm. It can drastically improve coating quality, part throughput, material usage and operator comfort. and keep a safe operating environment by removing contaminants and potentially explosive dust.Each unit is built to exact customer specifications by our expert craftsmen using the highest quality parts and materials.

view details

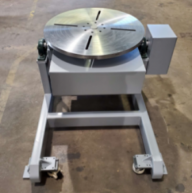

RM-4 Manual Tilting Turntable

RM-4 turntables are an economical option to adding industrial strength turntables to a thermal spray process. The products standard table top is 24” in diameter with a 90 degree manual tilt. However, each turntable is custom built allowing for faceplates to be able to range from 18” to 48”, allowing the table to fit the needs of the customer.

The standard tables are fitted with a digital controller that regulates RPMs. An additional option for the RM-4 is an electronic tilt option.

RM 34 60” x 60” Horizontal/Vertical Traverse

Specs:

- Horizontal Stroke: 60” with 3” acceleration & deceleration

- Vertical Stroke: 60” with 2” acceleration & deceleration

- Horizontal & Vertical speed: 1-150 SFPM (opt. 200 SFPM)

- Stepping capabilities of 1/8”, 1/4”, 1/2” on both axes

- Programs: step horizontal, step vertical, step both or step none

- Jog: up, down, right, left, with speed adjustments

- Limit switches on slide adjustment

- Air powered counter-balance for torch

RM-1000 Robotic Package

The RM-1000 Robot/Booth insures the right move, every time.

- Relieves operator pressure

- Guarantees consistent coating quality

- Robot torch manipulator attaches to standard spray booth

RM-52 Traversing Turntable and Spray Booth

Specs:

- Spray booth with turntable that reciprocates vertically between 1” to 6”

- Spray booth dimensions: 24”x24”x24” with 8” exhaust outlet

- Spray sample fastened to turntable which passes in front of booth opening

- Turntable rotation speed: 10 – 360 R.P.M.

- Vertical Traverse speed: 2 – 40 I.P.M.

RM-50 Wire Reel Payoff Unit for Arc System

Specs:

- Unit capable of holding two 250 lb wire reels

- Unit motorized with variable speed

- Each side equipped with dancer tension feedback

- Ensures constant tension for Arc Spray System

- Unit is low profile to ground for ease of loading

- 115 volt, 15 amp power required

RM 36 Clam Shell Exhaust

Specs:

- Exhaust hood to fit on lathe bed

- Accommodates rolls from 10” to 30” diameter

- Sides have adjustable shutters

- Unit 30” wide, 52” diameter

- Suitable for 3,500 CFM

- Unit closes around part to be sprayed

- Customer to supply jigging to mount unit to lathe

RM 35 Gantry Robot Cell

Specs:

- Acoustical Room - 8 ft. x 8 ft. x 10 ft. high

- 5-axes Gantry Robot

- 2-axes Turntable

- Flat Wall Exhaust Plenum

- A-axis stroke: 48 inches, horizontal top speed 150 feet per minute

- B-axis stroke: 36 inches, horizontal top speed 150 feet per minute

- C-axis stroke: 24 inches, vertical top speed 150 feet per minute

- D-axis: rotation 180 degrees, top speed 16 RPM

- E-axis: rotation 360 degrees, top speed 16 RPM

- Spray Torch load capacity: 30 pounds

- Jog & teach programming, on-screen editing, and security code

RM-21 Flat Wall Plenum

Specs:

- Plenum Dimensions: 7’W x 5’H x 2’D

- Suitable for 8,000 CFM

- 24” diameter outlet on plenum back

- Moveable louvers on front grate

RM-18 Pipe Rolling Cart System

Specs:

- 3 carts per system

- Rotates pipe from 1 to 170 surface feet per minute

- Variable speed

- Hand crank for size adjustment

- Accommodates 6” to 36” diameter pipes

- 30 foot long traverse, speed 2” to 50” per minute

RM-12 Wet Collector Exhaust Unit

Specs:

- 2,500 – 3,000 CFM

- 7.5 H.P., 1,800 R.P.M. Motor

- Dimensions: 45” W x 40” D x 92” H

- Inlet adapter for 12” duct

- Viewing windows

- Plumbing for draining and filling